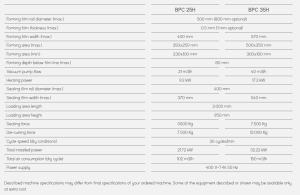

Blister packaging machine BPC 25H / BPC 35H

Automatic line machine suitable for manufacturing face-seal blister, full-sealed blister, full plastic blister and blister to blister.

Features

- Dedicated to the production of medium and long runs.

- Modular design through available options.

- Robust and accessible construction.

- Low operating and maintenance cost of the machine.

- Quick tool set change-over.

- PLC operated, touch-screen controlled.

- Steel-rule die cutter, which avoids misalignment in the cut.

- Film traction by chain conveyor.

- Automatic card feeder.

- Available in two sizes:

- 350×250 mm in the case of the BPC25H.

- 500×350 mm in the case of the BPC35H

- •EU safety rules compliance.

The most common optional extras are:

- Pressure forming to produce more detailed pieces.

- Customizable length of loading area.

- High frequency welding.

- Dedicated printing and coding system (flexographic printers, inkjet based coders, etc)

- Punching station for the euro-holder.

- Possibility to manufacture a blister to blister pack.

Operation

The BPC25H / BPC35H machines integrate all operations needed to manufacture a blister package, from forming the blister, loading of the product and sealing, to trimming operations.

Dimensions approx. (H x W x D)

1.800 x 1.120 x 9.860 mm (BPC 25H) – 1.800 x 1.320 x10.660 mm (BPC 35H)

Estimated weight

2.500 Kg (BPC 25H) – 3.500 Kg (BPC 35H)