Hamer Packaging Techology

|

HAMER is a European company founded in 1980 by the Schiess family of Swiss origin. It is currently run by the second generation together with a team of experienced professionals dedicated to providing solutions to your packaging needs. In our facilities, we design and manufacture equipment for the packaging market, especially thermoforming machines for the production of single-use plastic packaging, as well as automatic and semi-automatic lines for the production of blister packs. Our R & D & I capability distinguishes us and allows us to incorporate new solutions based on 4.0 technology, such as remote equipment management, or innovation in new materials such as cellulose pulp.    How we workOur commitment is to solve the problems of our customers, that is why we offer tailor-made solutions, that suit your needs. We achieve a high level of reliability as we integrate the entire process in our facilities, from the design by our technical team to manufacturing in the production department. We are able to propose the design you need, advise you on the selection of the most suitable solution, we will manufacture the mould that optimizes the performance and we will carry out the commissioning and starting up, guaranteeing the control of the whole process. During the life of the equipment we will accompany you giving the necessary technical support at all times to ensure the correct operation.  Why Hamer?More than 35 years in the market, we give you the experience that guarantees solutions. Thanks to our Swiss origins we maintain high standards of innovation and technological development.

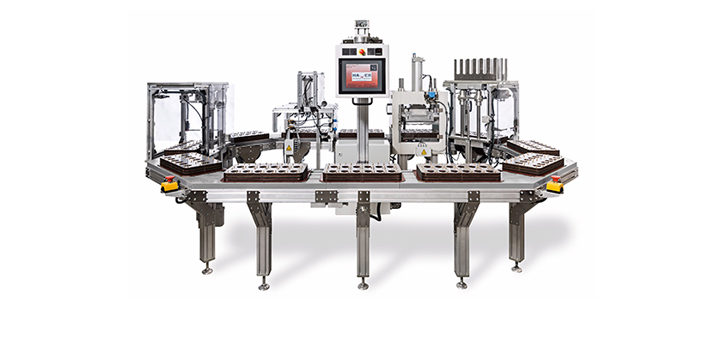

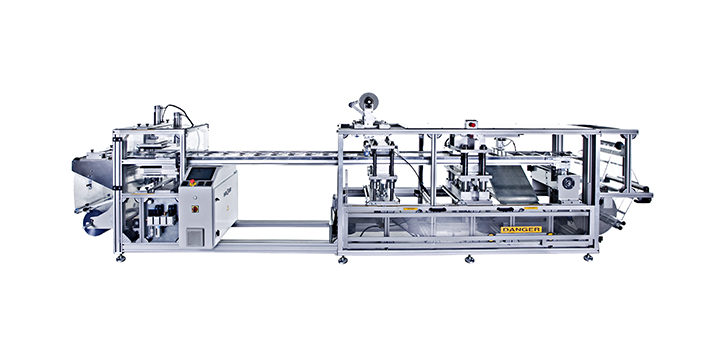

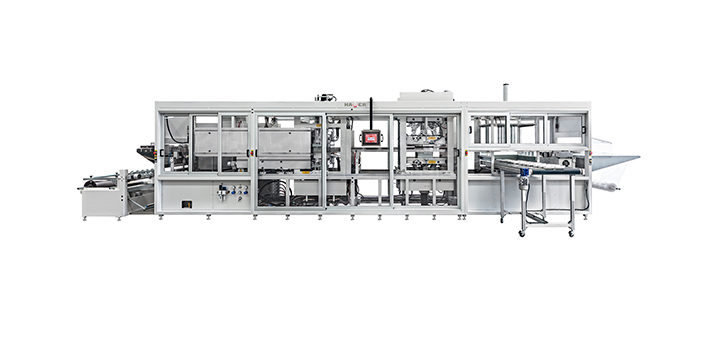

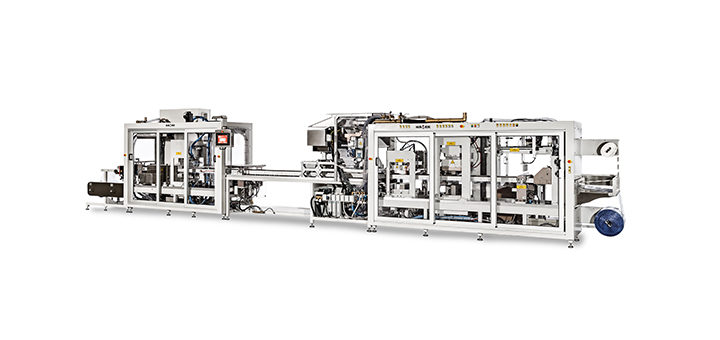

Through our multidisciplinary team, we control the process of design, manufacture, commissioning and starting up. Thermoforming and blister packaging solutionstailored to your needs We control every part of the process.In Hamer we design and manufacture machinery for the blister packaging and thermoformed industry. We are able to offer solutions perfectly tailored to the needs of our clients because we control every part of the manufacturing process: from design to set up. Our technical team is responsible for the design and they control every stage of production in our facilities. Once production is complete, we also carry out the commissioning and starting up of the equipment. RetailWhat is a blister?A blister is type of packaging done in thermoformed clear plastic that is mostly used in the marketing of small consumer products. Its use has spread since the blister pack is relatively cheap and permits the stored product to be viewed, providing extra quality check. Why use a blister?

Blister types

ThermoformingWhat is Thermoforming?Thermoforming is a process of transformation of a plain plastic foil in a three-dimensional shape through the application of heat, vacuum and air pressure. It is an inexpensive method that allows the production of single-use plastic parts with a wide variety of uses. For example, the packaging of a product or auxiliary carrying supports such as trays used in industrial production. Why use Thermoforming?

In which applications can be used?

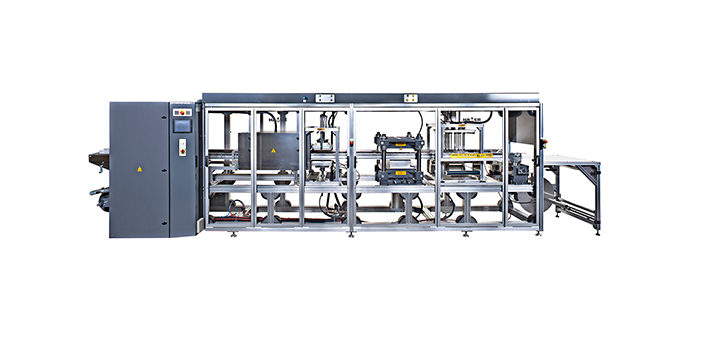

MedicalWhat is a medical blister?The medical blister is a container designed to contain all kinds of health-related devices for subsequent sterilization. Its medical use requires that the safety in its manufacture be maximum. The medical blister has the following characteristics:

We distinguish between the flexible medical blister of the rigid, more used for the packaging of medical devices. Applications of rigid medical blister

|

Em caso de interesse nos nossos produtos e queiram fazer uma consulta sem qualquer compromisso, aguardamos pelo vosso contacto, por telefone, email ou preenchendo o formulário que se segue: